Chunwang | Founded in 1998 | Stock code: 831880 | Stock name: Chunwang New Materials

Silica Gel Desiccant | Calcium Chloride Desiccant | Bentonite Desiccant | Other Types of Desiccant | Food Oxygen Absorber Professional Manufacturer

Manufacturer Direct Supply | Customization Available | Open for Agents, Distributors, and Dealers

Experience(Years)

Production Bases(㎡)

Workers(Total)

R&D Staff

Production Equipment

Capacity(Million-Pcs)

Professional Manufacturer of All Types of Desiccants and Food Oxygen Absorbers

Silica Gel Desiccants

$:Negotiable price, Free sample

Types: Transparent silica gel desiccant, orange silica gel desiccant, blue silica gel desiccant

Specifications: 0.5g – 1000g

Calcium Chloride Desiccants

$:Negotiable price, Free sample

Raw materials: anhydrous calcium chloride, calcium chloride dihydrate, anhydrous magnesium chloride

Specifications: 1g, 2g, 5g, 10g, 25g, 50g, 100g

TY Desiccants

$:Negotiable price, Free sample

Types: TY50 (general purpose), TY70 (special for precision electronics)

Specifications: 1g, 2g, 3g, 5g, 7g, 10g, 20g, 33g, 50g

Bentonite Desiccants

$:Negotiable price, Free sample

Types: conventional bentonite desiccant, biodegradable bentonite desiccant

Specifications: 1/3, 1/2, 1, 2, 4, 8, 16 (Unit)

Why Choose Us?

We have deep expertise in technology development, quality control, and market applications.

Listed on the NEEQ

Stock Code: 831880 | Stock Abbreviation: Chunwang New Materials

National Standard

BB/T 0049-2021 Packaging Desiccants National Standard Drafting Organization

National Standard

GB/T 41896-2022 Food Deoxidizers National Standard Drafting Organization

Certifications

ISO, BSCI, GMP, High-Tech Enterprise, Specialized and Innovative Enterprise Certification

Product Certifications

RoHS, REACH, TSCA, FDA, and Other Certifications for National or Regional Specific Requirements.

Packaging Materials

National Pharmaceutical Packaging Materials Registration No.: B20190000354

About Us

"Anhui Chunwang New Materials Co., Ltd." is a wholly-owned subsidiary of "Shenzhen Chunwang New Materials Co., Ltd."

Main Business

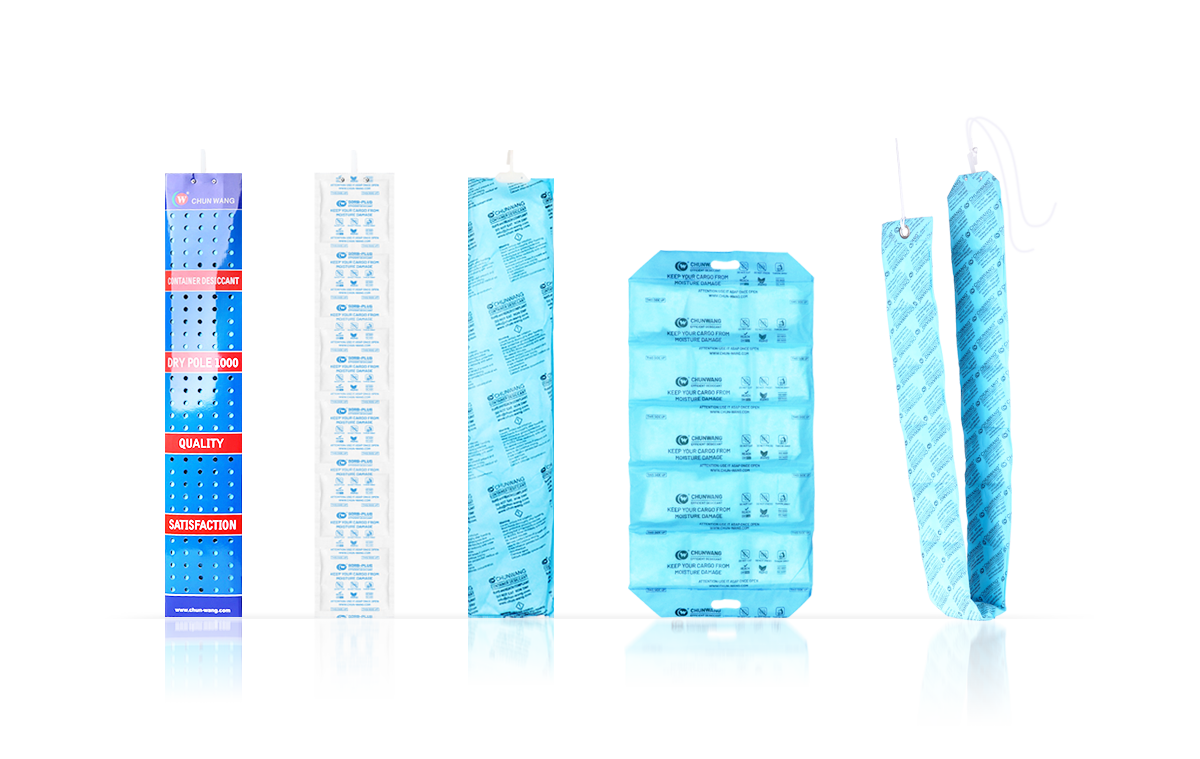

We specialize in the research, development, production, and sales of various desiccant products, including silica gel desiccants, calcium chloride desiccants, bentonite desiccants, activated clay desiccants, molecular sieve desiccants, fiber desiccants, food desiccants, pharmaceutical desiccants, container desiccants, car lamp desiccants, as well as food oxygen absorbbers.

Company History

“Shenzhen Chunwang New Materials Co., Ltd.” (formerly “Shenzhen Chunwang Moisture-Proof Pearl Factory”) was founded in 1998. After more than 20 years of development, Chunwang has grown into a large industrial group with a focus on “specialized development and scaled growth.” The company has established production bases in Shenzhen, Anhui, and Dongguan, and is in the process of building its own base in Heyuan, Guangdong. Chunwang has formed a mature market presence both domestically and internationally, covering all provinces, cities, and autonomous regions in China, as well as Hong Kong, Macau, Taiwan, Europe, North America, South America, Southeast Asia, and other regions.

Company Size

Chunwang Group owns a modern industrial factory covering 60,000㎡ (Shenzhen: 17,960㎡, Dongguan: approximately 15,000㎡, Anhui: 25,000+㎡), with over 450 professional packaging and supporting devices. The group employs more than 400 skilled workers, with scientific factory management, advanced equipment, and sufficient production capacity, achieving a daily production of up to 100 million PCS. The company also has over 15 professional engineers and technicians, ensuring that we stay at the forefront of technology and provide customers with comprehensive moisture-proof and preservation solutions.

Honors and Certifications

Chunwang has ISO 9001:2015 Quality Management System Certification and ISO 14001:2015 Environmental Management System Certification, as well as BSCI, GMP (with a 100,000-class dust-free workshop, National Pharmaceutical Packaging Materials Registration No.: B20190000354), National High-Tech Enterprise, and Specialized and Innovative Enterprise Certifications. Our products meet RoHS, REACH, TSCA, FDA, and other requirements. The company is equipped with advanced production equipment, testing instruments, and laboratories, and actively participates in the drafting of the BB/T 0049-2021 National Standard for Packaging Desiccants and the GB/T 41896-2022 National Standard for Food Oxygen Absorbers.

Related Links: Milestones | Company Culture | Photo Gallery | Test Reports | Selected Clients

Service & Support

Professional team, 7X24 hours service for you

Miss Liu

Gold Medal Salesperson

Miss Zhou

Gold Medal Salesperson

Miss Zeng

Gold Medal Customer Service

Miss Lan

Gold Medal Customer Service

Employee Creed

FAQ

What is DMF and Why is it Banned by the EU?

We often hear the term “DMF-free desiccants,” but what exactly is DMF? DMF stands for Dimethyl Fumarate (chemical name: Fumaric Acid Dimethyl Ester), a chemical mildew inhibitor with low toxicity and broad-spectrum antibacterial properties. It is particularly effective against mold and has been widely used in leather, footwear, sofas, and other textile products for mildew prevention. While DMF is mildly irritating, it is generally considered safe for humans in low doses. However, some manufacturers, considering Europe’s humid monsoon climate, have used DMF in higher-than-recommended amounts in certain products to achieve better mildew prevention. This has led to allergic reactions, acute eczema, and burns in consumers.

On March 17, 2009, the European Commission passed a decision (2009/251/EC) to prohibit the sale of products containing more than 0.1 ppm of DMF in EU member states. This regulation came into effect on May 1, 2009, and required the recall of products containing DMF from the market and consumers.

How Do DMF and Silica Gel Desiccants Differ in Their Anti-Mold Mechanisms?

DMF (Dimethyl Fumarate) is a chemical mildew agent synthesized from organic compounds. It works by penetrating the cell membranes of microorganisms and inhibiting mold growth within the cells.

On the other hand, silica gel desiccants are adsorbents. They contain numerous nanopores that absorb moisture from the air without requiring external conditions to aid in their function. Silica gel desiccants are inorganic oxides that prevent mold by absorbing moisture and thereby disrupting the environment that mold needs to grow.

Can Desiccants Be Included in Export Cargo Cartons? Do They Require Customs Declaration?

Desiccants can be placed in export cartons.

Scenario 1: If the exported product is a desiccant, it must be declared to customs.

Scenario 2: If a small amount of desiccant is used to prevent moisture damage to the goods, a customs declaration is generally not required. However, customs may inquire about it. This largely depends on the relationship between your freight forwarder and the customs authorities. The same applies to foreign customs clearance, where they might ask or inspect. If required, a simple declaration or explanation should suffice. Many foreign importers specify the use of desiccants, so in such cases, you can simply include them without much concern.

However, when exporting to the EU, a DMF inspection report is mandatory for desiccants. Without it, the products could be returned.

Can Silica Gel Desiccants Be Used in Shipping Containers?

No, silica gel desiccants are not suitable for use in shipping containers for two main reasons:

1)Low moisture absorption rate: Silica gel can only absorb about 30-35% of its weight in moisture, which is insufficient for the large volume of a shipping container. Therefore, it cannot meet the moisture control requirements for container transportation.

2)Temperature sensitivity: When the temperature exceeds 37°C, silica gel desiccants do not absorb moisture; instead, they may release water vapor. This characteristic makes silica gel unsuitable for ocean freight, where temperature fluctuations are common. In contrast, calcium chloride desiccants are effective in a temperature range of -5°C to 90°C, making them more suitable for the temperature variations encountered during container transport.

Currently, calcium chloride desiccants are the most appropriate choice for container shipments. They can absorb moisture up to 10 times more than silica gel, and they maintain their performance without releasing water even under varying temperature conditions during ocean transport.

What Are the Advantages of Molecular Sieve Desiccants Compared to Other Desiccants?

Molecular sieves are capable of distinguishing between molecules of different sizes, a task that is difficult for the human eye to detect. Their structure resembles a sponge, with numerous interconnected pores. Each gram of molecular sieve has an internal surface area of over 800 square meters. When different substances pass through the sieve, only smaller molecules can move freely, while larger molecules are either blocked or absorbed into the pores. This selective filtration gives the molecular sieve its name.

Common desiccants like calcium chloride and silica gel can reduce moisture levels in the air to about 0.4 grams per cubic meter. In contrast, molecular sieve desiccants can lower moisture content to below 0.01 grams per cubic meter, making the air much drier. Additionally, the moisture-absorbing capacity of molecular sieves is less affected by relative humidity. Even at a low relative humidity of 10%, they can still absorb significant amounts of moisture.

What is the Difference Between Desiccants and Oxygen Absorbers?

Desiccants and Oxygen Absorbers are often confused because they look similar and are usually packaged in small sachets marked with “DO NOT EAT.” Both are commonly found in snack packaging, but their functions are quite different:

1.Desiccants: As the name suggests, desiccants are used to absorb moisture. They help maintain a dry environment inside packaging, preventing rust, mold, and spoilage. Desiccants are used in a wide range of products like dried fruits, pharmaceuticals, electronics, clothing, furniture, wooden goods, and more.

2.Oxygen Absorbers: These are used to absorb oxygen, preventing the oxidation process that leads to food spoilage. While desiccants are used to control moisture, Oxygen Absorbers create an environment that limits oxygen, which is particularly useful for food packaging. Since food often contains moisture, using a desiccant would affect its taste, so Oxygen Absorbers help prevent oxidation without impacting the food’s moisture content.

What Measures Should Be Taken for Container Moisture Control?

1.Use Barrier Packaging Materials

Packaging goods in moisture-proof materials like aluminum foil bags or PE bags helps prevent humidity from building up inside the container. These materials also protect goods from direct contact with water during transport.

2.Avoid Moisture-Rich Packaging Materials

Materials like paper and wooden pallets contain moisture. When these materials are used, they can increase the likelihood of container condensation, especially in high-temperature conditions. Some cushioning and stabilization materials also contain moisture, which can evaporate in a heated container and increase humidity rapidly.

3.Use Container Desiccants

Container desiccants are the most direct and effective way to prevent moisture buildup. When used correctly, they can completely eliminate condensation inside the container, ensuring safe transport. Using moisture-absorbing barrier materials like corrugated cardboard can also reduce condensation risks.

What Are the Pros and Cons of Bentonite Montmorillonite Desiccants Compared to Silica Gel Desiccants?

Advantages: Bentonite montmorillonite desiccants have lower production energy consumption, less environmental pollution, a lower cost, faster adsorption speed, and a lower manufacturing cost compared to silica gel desiccants.

Disadvantages: The moisture absorption capacity of bentonite montmorillonite desiccants ranges from 18% to 24%, which is lower than that of silica gel, which can absorb around 30%. High-quality silica gel desiccants can absorb up to 35% of their weight in moisture.

Both bentonite montmorillonite and silica gel desiccants are safe, non-toxic, odorless, and non-corrosive, making them suitable for food packaging.

Industry Insights

Biodegradable Desiccant

It is widely recognized that non-degradable products, such as plastic goods, have caused significant pollution and destruction to soil, water bodies, and ecosystems due to their prolonged accumulation in the environment. In contrast, biodegradable products can naturally decompose after being discarded, greatly reducing their negative impact on the environment. Moreover, the development of biodegradable products often involves the use of renewable resources or recycled materials. This approach not only reduces the consumption of limited resources but also promotes sustainable use, aligning...

Why Is Silica Gel Desiccant The Most Common?

Many people, out of curiosity, have opened desiccant packets to find small, glass bead-like substances inside. While there are various types of desiccants on the market, the transparent granular type is the most commonly used. This type is known as silica gel desiccant, and its widespread use can be attributed to its excellent performance and features, making it a go-to choice across many industries. First, silica gel desiccant has outstanding adsorption properties and fast moisture absorption capabilities, able to absorb up to 30% of its own weight in moisture. It also boasts excellent...

Where Does The Moisture Inside A Container Come From?

Containers are not entirely sealed spaces—especially near the doors, there are often small gaps where outside moisture can seep in. Additionally, moisture is hidden in the cargo itself, the packaging materials, pallets, and even the wooden floors of the container. Since ocean shipping involves long transit times and significant temperature fluctuations between day and night, this trapped moisture can evaporate, condense into liquid droplets, and fall onto the cargo, potentially causing damage. A key point to note is that container wooden floors always contain some level of moisture, with the...

Which Preservatives Should Be Used For Preserving Dried Fruits?

The shelf life of dried fruits is typically affected by factors such as microbial contamination, light exposure, temperature, moisture, and oxygen. Therefore, to ensure the proper storage and preservation of dried fruits, it’s important to address these factors. First, during production, strict hygiene control is crucial to minimize microbial contamination at the source. Additionally, selecting the right packaging materials and storage conditions is vital. Ultraviolet (UV) light can trigger oxidation reactions in the fruit, causing discoloration and spoilage, while high temperatures can...

Why Is Sea Freight The Primary Mode Of Transportation For Global Trade?

Did you know? Despite the occasional moisture issues that can occur during container shipping, sea freight remains the most dominant mode of transportation for global trade, primarily because of its cost advantages over air and rail transport. When you need to move large quantities of goods over long distances, a cargo ship acts like a massive, mobile warehouse, handling everything in one go—and at a surprisingly low cost. Even more impressive, sea freight is the only transportation method that can reach every corner of the globe, making it indispensable for global trade. However, container...

How To Reuse Desiccants?

Many friends often ask how to reuse desiccants. First, it's important to clarify that not all desiccants can be reused. Chemical adsorption desiccants, for example, undergo a chemical reaction when they absorb moisture, forming new substances, which makes the process irreversible and unsuitable for reuse. Take calcium chloride desiccants, for instance. The molecules in calcium chloride have a strong affinity for water and react chemically with moisture to form hydrates, thus achieving moisture absorption. However, once calcium chloride has absorbed enough moisture and formed hydrates, it...