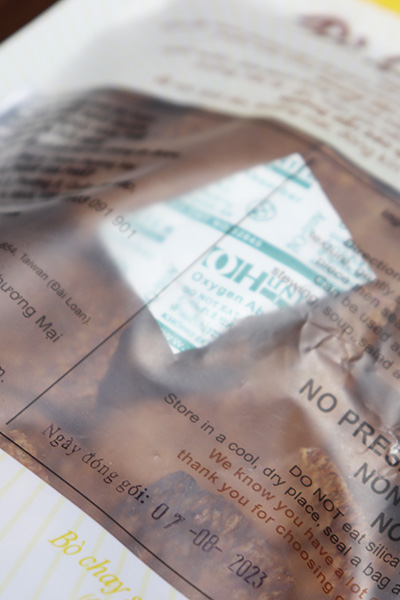

Oxygen Absorbers

Key Attributes

- Types: general-purpose, nut-specific, moisture-proof, pressure-stabilizing, dual-absorbing, odor-removing, sterilization, and oxygen Indicator types.

- Models: 20#、30#、50#、100#、150#、200#、250#、300#、500#、800#、1000#

- Appearance: Single-piece / Chain type.

Product Quote

$:Negotiable price, Free sample

Introduction:

Oxygen absorbers, also known as deoxidizers, are not food additives. Originally developed in Japan, they are sometimes referred to as “oxygen scavengers” Their primary function is to absorb oxygen within food packaging, reducing the oxygen level to below 0.1% within a specified timeframe and maintaining this low level for an extended period. These absorbers help prevent food from oxidizing and spoiling, offering a stable reaction without harmful gas emissions or side effects, making them widely used in the food production industry.

Our company specializes in advanced oxygen absorber technology, offering a wide range of products including general-purpose, nut-specific, moisture-proof, pressure-stabilizing, dual-absorbing, odor-removing, sterilization, and oxygen Indicator types. These absorbers effectively eliminate residual oxygen in food packaging, maintaining an oxygen-free environment over time. They help inhibit the growth of mold, aerobic bacteria, and grain pests, prevent spoilage, discoloration, rancidity in fats, and preserve the taste and nutritional value of food by protecting against vitamin loss.

Why use oxygen absorbers?

Common preservation methods include cold storage, nitrogen flushing, and vacuum sealing, each of which has significant drawbacks.

- Cold storage: Requires stringent environmental conditions and high transportation costs.

- Nitrogen flushing: Leaves a residual oxygen level of about 3%-5%, involves high initial equipment costs, and has poor long-term effectiveness.

- Vacuum sealing: Demands high-quality packaging and is susceptible to temperature variations, resulting in suboptimal long-term preservation.

Only food-grade oxygen absorbers combine convenience, affordability, safety, complete oxygen removal, and the ability to maintain the original color, aroma, and flavor of food over extended periods.

Food-grade Oxygen Absorber Usage Calculator (Click to enter)

This calculator is designed based on GB/T 41896-2022 Food-Grade Oxygen Absorbers (National Standard).

Our company is one of the drafting units of the GB/T 41896-2022 Food-Grade Oxygen Absorbers (National Standard), holding a leading technical position and professional expertise in the industry. Our products are distinguished by their superiority and innovation, with extensive experience in technical research, quality control, and market application. We are dedicated to providing efficient, safe, and eco-friendly food preservation solutions for our clients.

Advantages of Us

- Established in 1998, with over 20 years of expertise in the research and production of desiccants and oxygen absorbers.

- Stock code: 831880; Stock abbreviation: Chunwang New Materials.

- Three production bases in Shenzhen, Dongguan, and Anhui, totaling 60,000㎡.

- Drafting organization for the national standard BB/T 0049-2021 for packaging desiccants.

- Drafting organization for the national standard GB/T 41896-2022 for food-grade oxygen absorbers.

- Certified by ISO, BSCI, GMP, and recognized as a “High-Tech Enterprise”, and a “Specialized and New Enterprise (SNE)” .

- Fully compliant with RoHS, REACH, TSCA, and FDA certifications.

- Registered with National Pharmaceutical Packaging Material Registry: B20190000354.

Hotline

Attributes:

Brands

Chunwang (for domestic trade), Ohunter (for foreign trade).

Nominal Oxygen Absorption Capacity

>3 X / >6 X

Packaging Materials

Dust-proof film, high-transparency dust-proof film, triple-protection film, high-transparency triple-protection film, tear-resistant film, non-woven deoxygenation film.

Main Components

Iron-based: Reduced iron powder, activated carbon, diatomaceous earth, sodium chloride, water.

Chemical Formula

Fe+H2O+O2→Fe(OH)3 | 2Fe(OH)3=Fe2O3 + 3H2O Fe2O3

Product Types:

Nut-Specific Oxygen Absorber

Features:

1)The deoxygenation efficiency is high, and the oxygen in the packaging bag can be completely absorbed within 30 minutes to 2 hours, creating a state similar to vacuuming.

2)1g of oxygen absorber can absorb 140-160ml of oxygen.

3)Suitable for low water activity foods, maintaining oxygen absorption performance even in low-moisture environments.

Applications:

Sunflower seeds, peanuts, walnuts, pine nuts, pumpkin seeds, macadamia nuts, etc.

Precautions:

It takes effect quickly and generates heat. It must be used within 30 minutes after unpacking.

Moisture-Proof Oxygen Absorber

Features:

1)Dual functions of moisture absorption and oxygen removal, keeping food at low water activity and effectively preventing mold.

2)1g of oxygen absorber can absorb more than 120ml of oxygen.

3)Moisture absorption rate ≥30% under 90% RH conditions.

Applications:

Foods with high moisture content, such as betel nuts.

Precautions:

Moisture-dependent; requires environmental moisture to react and is not suitable for dry packaging.

Pressure-Stabilizing Oxygen Absorber

Features:

1)Release an equal amount of carbon dioxide while absorbing oxygen to prevent packaging shrinkage.

2)Non-iron based, contains no metal components, and can pass metal detectors.

3)Safe, eco-friendly, biodegradable, microwaveable (unlike other iron-based types), and rust-free.

Applications:

Canned foods, nitrogen-flushed pastries, museum sealed glass cabinets, etc.

Precautions:

Not suitable for hollow packaging, foods that react with carbon dioxide, or alkaline foods.

Dual-Absorbing Oxygen Absorber

Features:

1)Absorbs both oxygen and carbon dioxide, preventing package expansion.

2)Provides some moisture absorption.

3)Mild deoxygenation with relatively stable temperature changes.

Applications:

Red dates, coffee beans, and other foods that may generate carbon dioxide during storage.

Precautions:

Slow-release type; not suitable for packaging that requires rapid deoxygenation.

Deodorizing Oxygen Absorber

Features:

1)Absorbs sulfur compounds and ammonia, helping to neutralize odors.

2)Capable of absorbing some volatile organic compounds, enhancing its deodorizing effect.

Applications:

Ideal for foods and pharmaceuticals that require both oxygen removal and odor control.

Precautions:

Primarily designed for deoxygenation, with deodorizing as a supplementary function. Best suited for products with minimal off-odors and should not be compared to specialized deodorizers.

Sterilizing Oxygen Absorber

Features:

1)Effectively kills E. coli present in food.

2)Successfully eliminates Shigella bacteria.

3)Capable of eradicating other pathogenic microorganisms with a sterilization rate of up to 99.9%.

4)1g of the absorber can remove over 120ml of oxygen.

Applications:

Suitable for foods that require stringent microbial control.

Precautions:

This is a slow-release type of oxygen absorber and is not suitable for packaging that demands rapid oxygen removal.

High-Efficiency General-Purpose & Oxygen Indicator Type:

For situations without specific requirements, the high-efficiency general-purpose type should be the first choice. For users needing oxygen level indication, custom oxygen absorbers with color-changing indicators can be provided.

Application Overview:

Application:

A. Pastries and Baked Goods: Mooncakes, European cakes, waffles, Swiss rolls, ma shu, mung bean cakes, rice cakes, walnut crisps, wife cakes, light crisp cakes, almond crisps, etc.

B. Poultry and Meat Products: Beef jerky, pork jerky, chicken wings, sausages, ham, meat snacks, shredded pork, cured duck, etc.

C. Nuts and Roasted Seeds: Pistachios, macadamia nuts, almonds, pine nuts, pecans, walnuts, chestnuts, peanuts, sunflower seeds, pumpkin seeds, flavored beans, etc.

D. Dried Seafood: Dried abalone, cured fish, dried scallops, shredded squid, dried shrimp, roasted fish fillets, etc.

E. Other Dried Goods: Tea leaves, seaweed, longan, dried lychee, dried mushrooms, dates, wild vegetables, dehydrated vegetables, beans, persimmon cakes, dried sweet potatoes, rice, etc.

F. Pharmaceuticals and Health Products: Traditional Chinese medicine, pharmaceuticals, health supplements, etc.

G. Non-Food Items: Precision instruments, military products, books, artifacts, tobacco, etc.

H. Animal Feed: Fishing bait, pet food.

Precautions:

1)Iron-based oxygen absorbers are not microwaveable; organic types are suitable for microwaves.

2)Oxygen absorbers cannot prevent spoilage caused by anaerobic bacteria in food.

3)Foods with high fat content or moisture require triple-protection films.

4)Do not submerge oxygen absorbers in food liquids.

5)Alkaline foods or foods that react with carbon dioxide should not use pressure-stabilizing oxygen absorbers.

6)All moisture-proof oxygen absorbers must use High air permeability, triple-protection films.

7)Moisture-proof oxygen absorbers are not suitable for dry foods.

8)Food packaging should have an oxygen permeability rate below 20ml/m²·24h·25°C, such as KOP/CPP, NY/PE, KNY/PE, KPET/PE, PET/AL/PE, and should not use packaging with high permeability like OPP/CPP, PP, or PE film bags.

9)After opening the oxygen absorber packaging, use and seal the preserved items within 1-2 hours. Reseal any unused absorbers promptly after expelling air from the original bag to prevent deactivation.

10)For fast oxygen-absorbing types, use within 30 minutes of opening.

11)The recommended operating temperature for food-grade oxygen absorbers is generally between -5°C to 40°C; effectiveness declines below -5°C.

12)Food-grade oxygen absorbers may release a small amount of heat during operation, which is a safe and normal reaction.

Related Link: Product Test Reports >>

Related Link: Production Environment >>

Service & Support

Professional team, 7X24 hours service for you

Miss Liu

Gold Medal Salesperson

Miss Zhou

Gold Medal Salesperson

Miss Zeng

Gold Medal Customer Service

Miss Lan

Gold Medal Customer Service