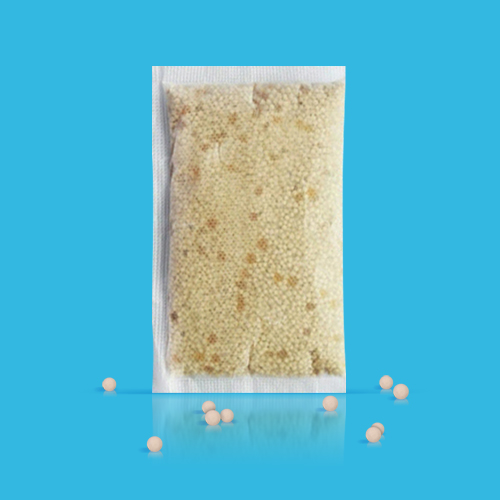

4A Molecular Sieve Desiccants

Key Attributes

- Features: Excellent moisture absorption performance in low humidity environment

- Types: No color change indicator added, color change indicator added

- Specifications: 1g-500g

- Packaging material: Aiwa paper, transparent wax paper, etc.

- Edge sealing: Three-side sealing

- Printing: Chinese, English and Japanese multi-language version

Product Quote

$:Negotiable price, Free sample

Introduction:

Molecular sieves are materials with a microporous structure, commonly used to adsorb and remove moisture and other gas molecules from the air. The pores in molecular sieves are highly uniform, allowing for selective adsorption based on molecular size. This characteristic makes them widely used in drying, separation, and purification processes.

Types of Molecular Sieves:

Molecular sieves are typically categorized by their chemical composition and pore size. The main types include:

- 3A Molecular Sieve: With a pore size of about 3Å (0.3 nanometers), it is mainly used to adsorb water molecules but excludes larger ones like methanol and ethanol.

- 4A Molecular Sieve: With a pore size of around 4Å (0.4 nanometers), it can adsorb smaller molecules such as water, methanol, and ethanol.

- 5A Molecular Sieve: With a pore size of about 5Å (0.5 nanometers), it is suitable for adsorbing slightly larger molecules like n-hexane.

- 13X Molecular Sieve: With a pore size of approximately 10Å (1 nanometer), it is ideal for adsorbing larger gas molecules such as carbon dioxide and hydrogen sulfide.

Working Principle of Molecular Sieve Desiccants:

The internal structure of molecular sieves consists of a vast number of evenly arranged micropores, which provide an extensive surface area. As gases pass through, these micropores trap and adsorb gas molecules. Due to their strong adsorption capacity, 4A molecular sieves are often used as desiccants. They are highly effective even in environments with low humidity or high temperatures, ensuring reliable drying performance.

| Granularity Qualified Rate | >98% |

| Bulk Density | >720g/L |

|

Moisture Absorption Rate T=25°C,RH=80% |

≥23% |

| Water Content | ≤1.5% |

| PH | 7.0±0.5 |

| Recommend Dosage | 2g/L-2.5g/L |

This product uses 4A molecular sieve as its main material, which continues to perform exceptionally well in low-humidity environments. Common desiccants like silica gel and calcium chloride can reduce the moisture content in the air to around 0.4 grams per cubic meter. In contrast, molecular sieve desiccants can lower the moisture content to below 0.01 grams per cubic meter, making them even more effective at moisture absorption in low-humidity conditions.

*From the experimental curve, we can see that in high-humidity environments, the moisture absorption rate of 4A molecular sieves shows a significant difference compared to other common desiccants. However, in low-humidity environments, the moisture absorption ability of 4A molecular sieves stands out remarkably. This demonstrates that molecular sieve desiccants are particularly well-suited for low-humidity conditions, making them ideal for products that require a high level of dryness in their packaging environment.

It is suitable for products that demand extremely high levels of dryness in their packaging environment.

Commonly used for static drying in products like cameras, transformers, PCB boards, electronic components, and pharmaceuticals, where a highly dry packaging environment is critical.

Desiccant Dosage Calculator for Packaging(Click to Enter)

This calculator is designed according to the DIN 55474 German standard.

Our company is one of the drafting units of BB/T 0049-2021 for desiccants in packaging (national standard), holding a leading technical position and expertise in the industry. Our products are superior and innovative, with a solid foundation in technology development, quality control, and market applications. We are committed to providing customers with efficient, safe, and environmentally friendly solutions for mold prevention and moisture control.

Advantages of Us

- Established in 1998, with over 20 years of expertise in the research and production of desiccants and oxygen absorbers.

- Stock code: 831880; Stock abbreviation: Chunwang New Materials.

- Three production bases in Shenzhen, Dongguan, and Anhui, totaling 60,000㎡.

- Drafting organization for the national standard BB/T 0049-2021 for packaging desiccants.

- Drafting organization for the national standard GB/T 41896-2022 for food-grade oxygen absorbers.

- Certified by ISO, BSCI, GMP, and recognized as a “High-Tech Enterprise”, and a “Specialized and New Enterprise (SNE)” .

- Fully compliant with RoHS, REACH, TSCA, and FDA certifications.

- Registered with National Pharmaceutical Packaging Material Registry: B20190000354.

Hotline

Common 4A Molecular Sieve Desiccants

Transparent wax paper packaging molecular sieve desiccant

Aiwa Paper Packaging Molecular Sieve Desiccant

Related Link: Product Test Reports >>

Related Link: Production Environment >>

Service & Support

Professional team, 7X24 hours service for you

Miss Liu

Gold Medal Salesperson

Miss Zhou

Gold Medal Salesperson

Miss Zeng

Gold Medal Customer Service

Miss Lan

Gold Medal Customer Service